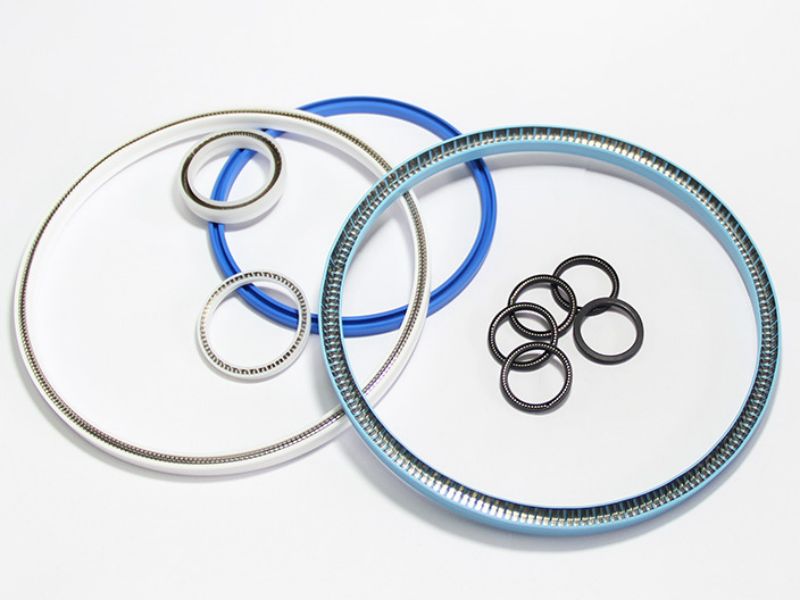

Pan plug Seal _ Spring energy storage ring

The spring energy storage ring is a kind of high-performance seal which is equipped with corrosion-resistant metal energy storage spring inside and fluorinated engineering plastic jacket outside. The sealing ring is installed in the sealing groove, the spring pressure gives the permanent elasticity of the sealing jacket and the system pressure makes the sealing lip close to the groove sealing surface, thus forming an excellent sealing effect.

Overview of working principle:

The spring energy storage ring is a kind of high-performance seal which is equipped with corrosion-resistant metal energy storage spring inside and fluorinated engineering plastic jacket outside. The sealing ring is installed in the sealing groove, the spring pressure gives the permanent elasticity of the sealing jacket and the system pressure makes the sealing lip close to the groove sealing surface, thus forming an excellent sealing effect. The spring can provide permanent elasticity and vibration compensation to the seal jacket to compensate for the wear of the seal lip and the slight eccentricity of the part fit, and can continue to maintain a good seal effect under high or low pressure.

Performance advantage

The spring energy storage seal ring is a special seal developed for the application environment of high temperature corrosion, ultra-low temperature, no lubrication and low friction. The combination of different formulations of fluorine-containing engineering plastic composite materials, advanced engineering plastics and corrosive metal springs can fully meet the increasingly demanding work requirements in the industry. In addition to the sealing application in high temperature corrosion environment, because the sealing lip has low friction coefficient, stable sealing contact pressure, excellent pressure resistance, allowing large radial yaw, etc., it can also be used in reciprocating and high-speed rotation conditions; Spring energy storage ring has better sealing performance and service life than rubber products.

Energy storage spring Overview:

The spring energy storage ring selects the appropriate spring type and spring material according to the movement mode of the matching surface and the sealing medium. The metal energy storage spring is installed inside the U-shaped jacket and provides the U-shaped lip compensation force, making the seal have permanent elasticity, thereby reducing the impact of changes in working pressure, temperature or medium form. In addition to corrosion resistance, energy storage springs also have two important characteristics: pressure load and compression deformation. The pressure load determines the wear of the pan ring shell and affects the sealing ability of the seal. The amount of compression deformation determines the ability to compensate for the wear of the flooding seal ring and the change of the seal groove tolerance.